This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Product Development - future now

Creanex has expertise that covers engineering and construction as well as tests and measurements. With our special expertise we can help our customers to succeed in their own business. The scope of cooperation is always separately agreed upon for each project.

It goes without saying, when working with us, that we keep in touch with our customers as a project proceeds and always keep them updated. It is always easy to contact us, and the team can be quickly summoned when necessary. We enjoy our work, and our customers see it in our keen attention, flexibility, and high-quality workmanship.

Together with our customers we want to forge a future where nothing is impossible. We are not only following the latest developments but are constantly working to spearhead them. The trust we have gained is reflected in our long-standing customer relationships, and in the fact that when our customer continues a project, it will also continue with us.

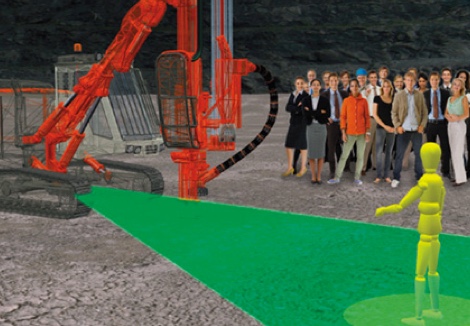

Concept Planning – from Ideas to Products

Developing a new idea into a product is a fascinating process. In many cases it is also a complex and high-risk investment. Creanex complements concepting with fresh ideas and visions that, however, also understand the demands of machine engineering. By outsourcing the concepting to Creanex, our customers are able to free significant resources to their core business.

Concepting is a cost-effective way to proceed from ideas to products. Concepting examines the serviceability of product ideas and their critical points. Always based on an agreed scope of work, we innovate solutions, evaluate alternatives, and eliminate risks in order to benefit our customer.

This generates reliable information to support the decision to start the development of a product. Information gained early on will help in avoiding the possibility of very expensive pitfalls later.

Starting with Objectives and Interfaces

A description of the objective is usually enough to begin the concepting process with. Different alternatives are then produced during conception. Together with the customer, we decide which solution will be examined further and to which interfaces the outcome should match. Examples of different interfaces are mechanics, hydraulics, electric systems, sensoring and automation, and control.

If the customer so wishes, Creanex can also assume responsibility for the manufacture and installation of components, as well as testing the whole concept. Measurements in different phases will give a good idea of how the solution has responded to the set objectives.

Our successful experience has shown that the development of control systems can also be approached through concepting.

TEAM EXCITED ABOUT THEIR WORK ENSURES HIGH CLASS END RESULT

Measuring Defines and Refines Goals and Verifies Results

In the development of work machinery, the role of measuring is essential, and testing as a part of development work is an agile way to proceed in small and effective steps towards the goal.

The objectives are crystallized when you know the performance of the machine or equipment, and the factors that affect it. Measurements before and after alterations provide a solid basis for assessing which aspects were affected and if the effects were as expected.

More than Reports

Creanex implements and reports on measurements according to a plan drawn up with the customer. The outcome of measuring projects need not, however, be only in reports. A project can also produce proposals for action, as well as tool applications for processing, analysing, and displaying the results.

Gathering the Information

For measuring purposes, connections can be made to commonly used machine control buses, and the machine’s own control and measurement data can be utilised. As the measurement system of Creanex supports the simultaneous monitoring of several measuring channels, the machine can be equipped with sensors that gather extra information. The gathered data is stored in a synchronised form, making the results comparable with one another. Our tools for analysing measurement data also enable connecting video image as a part of the measurement.